KRONES: Optimizing parts and on-demand spares for customers using 3D printing

Krones: complete food and beverage production lines

Every day, millions of glass bottles, cans and PET containers run through a Krones line. Krones is a leading manufacturer of complete systems for breweries, beverage bottlers and food producers. Its production lines fill packages, add labels, and perform quality control on the products. As a global market player in the beverage and packaging industry, Krones provides comprehensive solutions that customers, such as Coca-Cola and Heineken, rely on heavily.

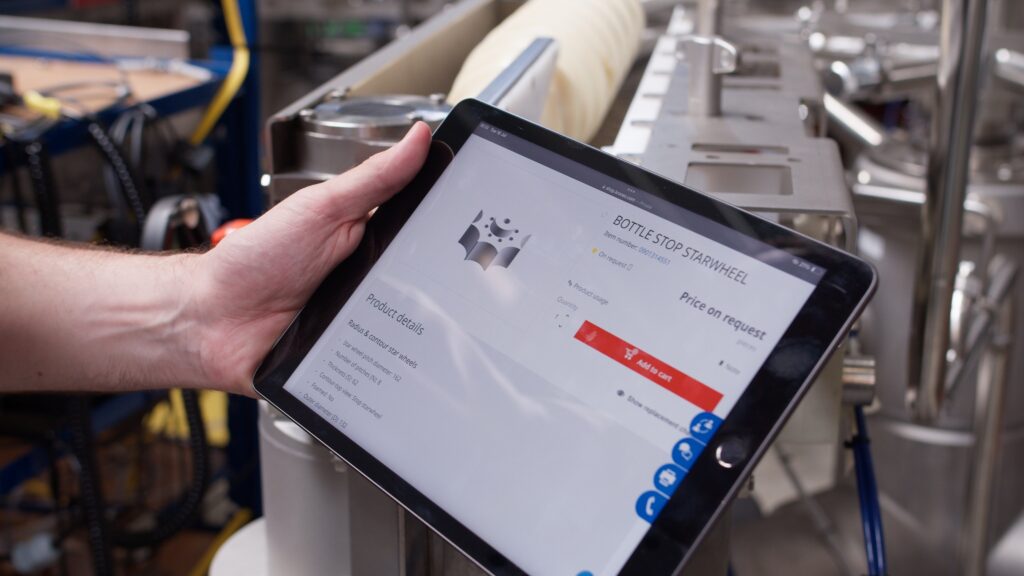

3D printing parts and spares

To help customers get even more uptime, develop parts faster or create emergency spare parts, Krones turned to 3D printing. Outsourcing the production of prototypes is very expensive and often could take weeks. With the use of UltiMaker 3D printers, prototypes were able to be produced in a day, or even in hours in some cases. By prototyping faster, Krones tested and iterated on their designs faster, ensuring that new parts performed better and lasted longer. This has helped customers with more reliable machines, higher uptime and a smaller environmental footprint.

telling the story through video

For this story, we’ve created a whole campaign of content assets. The main story shows the use and benefits of 3D printing at KRONES. For it’s promotion, various social media short videos with quotes were created. For the Ultimaker website, a story was written to explain the details. This case and the created contents were also used in webinars and at various booths on shows.