There are many different 3D printing techniques. STMEDIA focusses on the two most popular ones; FDM and Stereolithography (SLA). Luckily the differences between the two are very clear. So it’s usually easy to choose the right printing technique.

In general, FDM is for functional tools and parts. SLS is for visual stuff, with a super smooth surface and extreme small details.

FDM

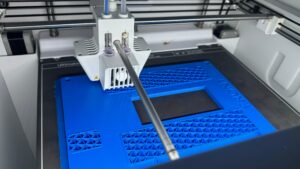

Also known as Fused Deposition Modeling, FDM is basically melting a polymer, pushing it through the brass/steel nozzle and adding layer by layer. The nozzle is like a fine liner, drawing a thin plastic line on top of the build plate or a previous layer. After each layer, the buildplate moves 1 layer down so the next can be printed.

Highlights

- Materials: Wide range of materials with very different mechanical properties. Super strong, flexible, ESD-safe, food-safe, heat resistant, chemical resistant, and many more properties.

- No hassle: Printing is as easy as making a microwave pizza. Import the 3D design in the software, select material and preferences, send print job to printer. Insert right material. Change nozzle if needed (95% of prints are 0.4AA core) and hit print. Easy does it.

- Minimal post-processing: FDM prints usually only need minimal post processing. Unless you have special materials such as PVA which you need to dissolve in water. But most people don’t need that.

- Safe: FDM printers are very safe. It’s advised to use closed printers with HPA filters when using materials with lots of ultrafine particles. Nylon with carbonfibre is amazing, but has indeed lots of particles escaping.

Stereolithography (SLA)

Stereolithography, or SLA in short, is a 3D printing technique that works with a resin “bath”. Underneath the resin is a monitor that emits UV light instead of regular light. This high-resolution screen lights up layer after layer, while the buildplate moves up, out of the resin bath. Since there is no physical nozzle that has to move around, each layer costs only 15-60 seconds. The layer height is also significantly thinner than FDM, giving it an extremely smooth surface on the sides.

FDM printers have a nozzle ranging from 0.2mm to 1mm, with 0.4mm as a standard. Resin printers use pixels on high resolution screens, which are much smaller, 0,019 X 0,024mm. This is why SLA printers give extremely detailed and smooth prints.

- Strong point: Extremely high resolution, smooth surface quality. Final-production quality surfaces.

- Materials: Very minimal options. Some very stiff/hard materials. Some that are similar to ABS. And some reasonably flexible materials.

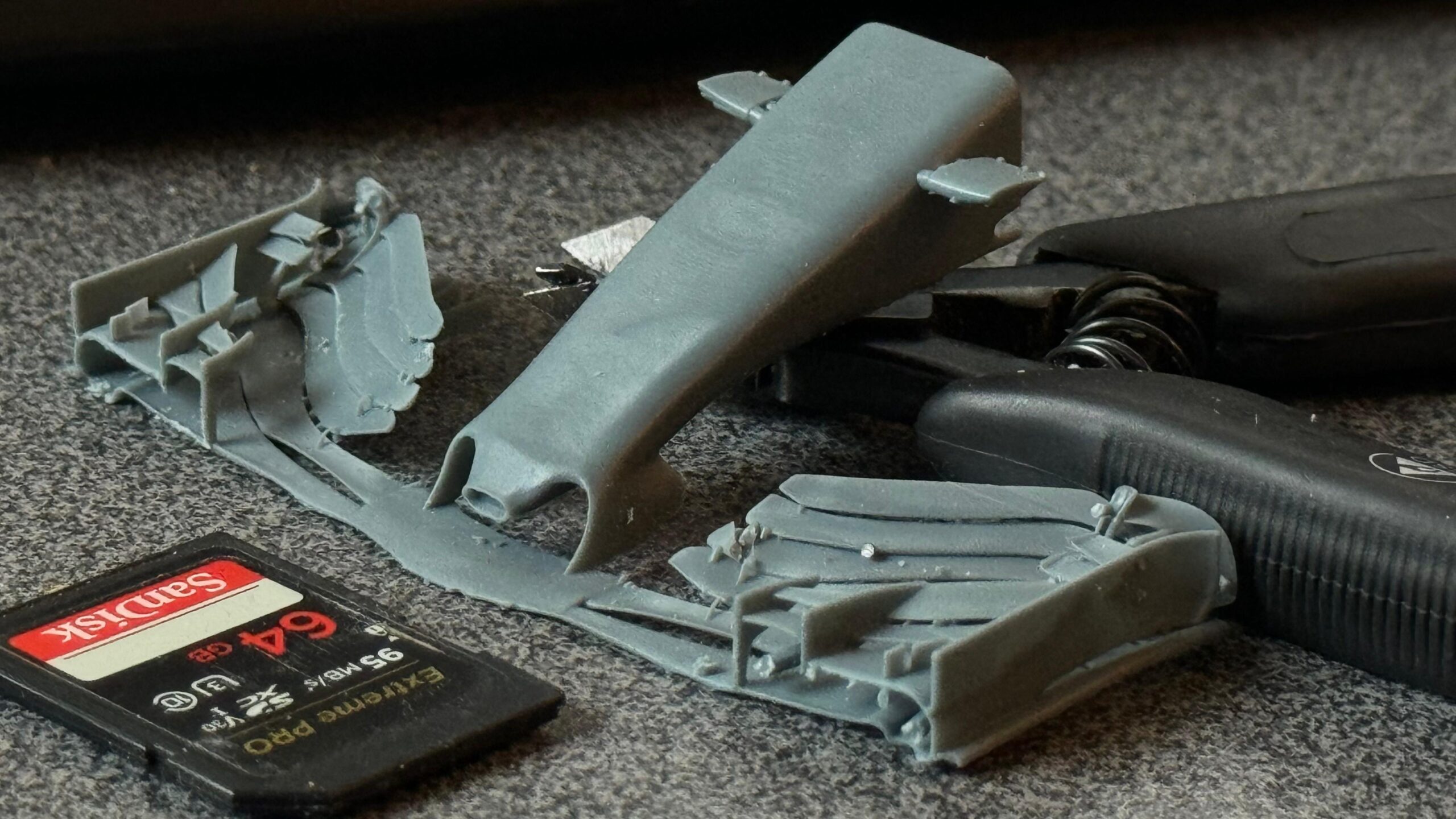

- Hassle: This is the big downside of SLA printing. The technology is very sensitive. When something goes wrong, there is a chance you need to perform maintenance on your printer. When things go right, you still need to clean the seriously dirty print, and cure it using UV light. Getting resin on your hands means you will smell and taste it four hours. I have no idea why, but no matter how hard you try to work cleanly, you wíll taste it at some point. Cleaning your print requires Isopropyl alcohol (IPA). Breathing it’s fumes can make you feel dizzy.

SERVICES

STMEDIA uses 3D printing as one of the many tools we have at our disposal. While we do not offer 3D printing as a stand-alone service, we can offer assistance.

What we offer

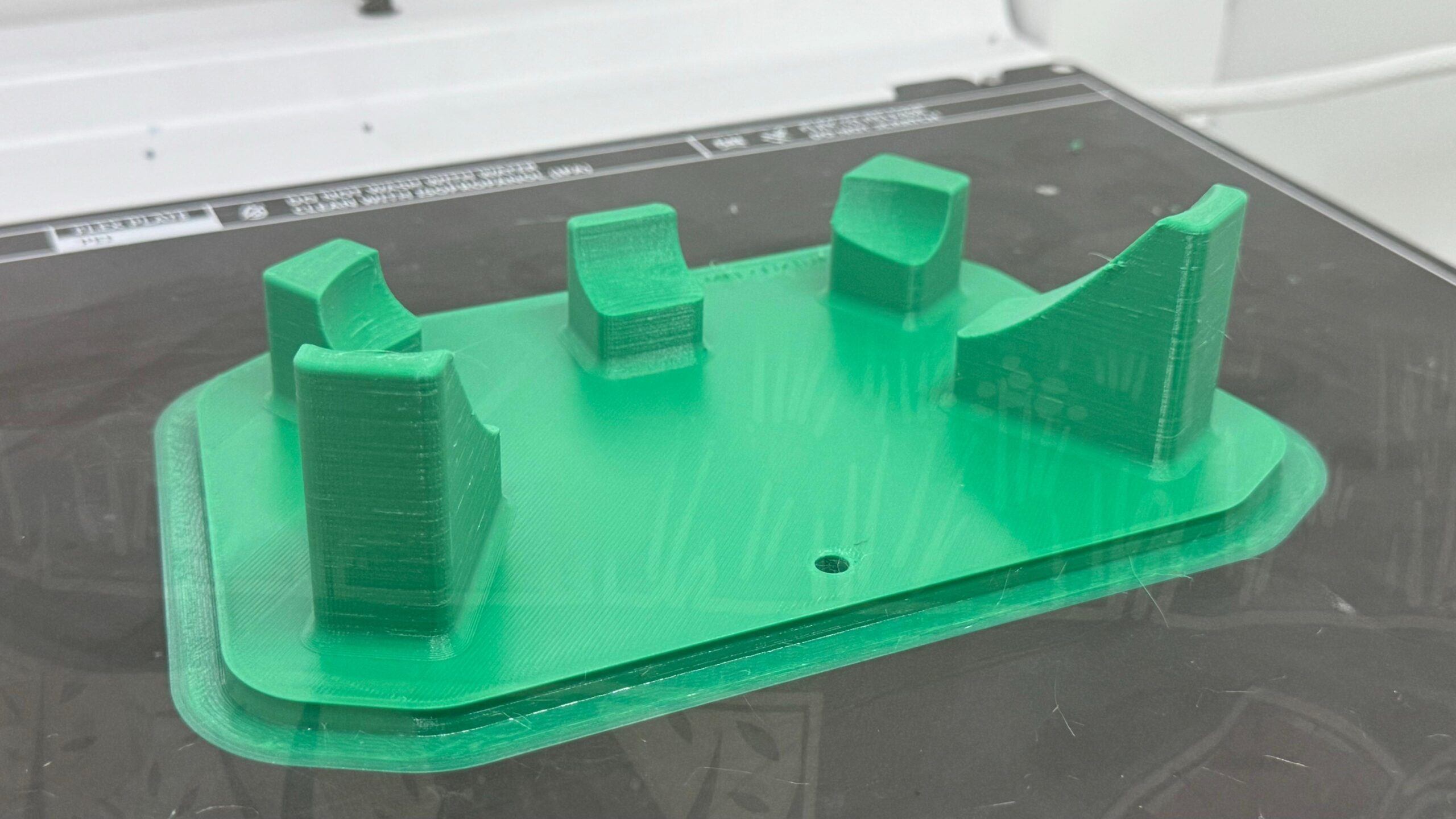

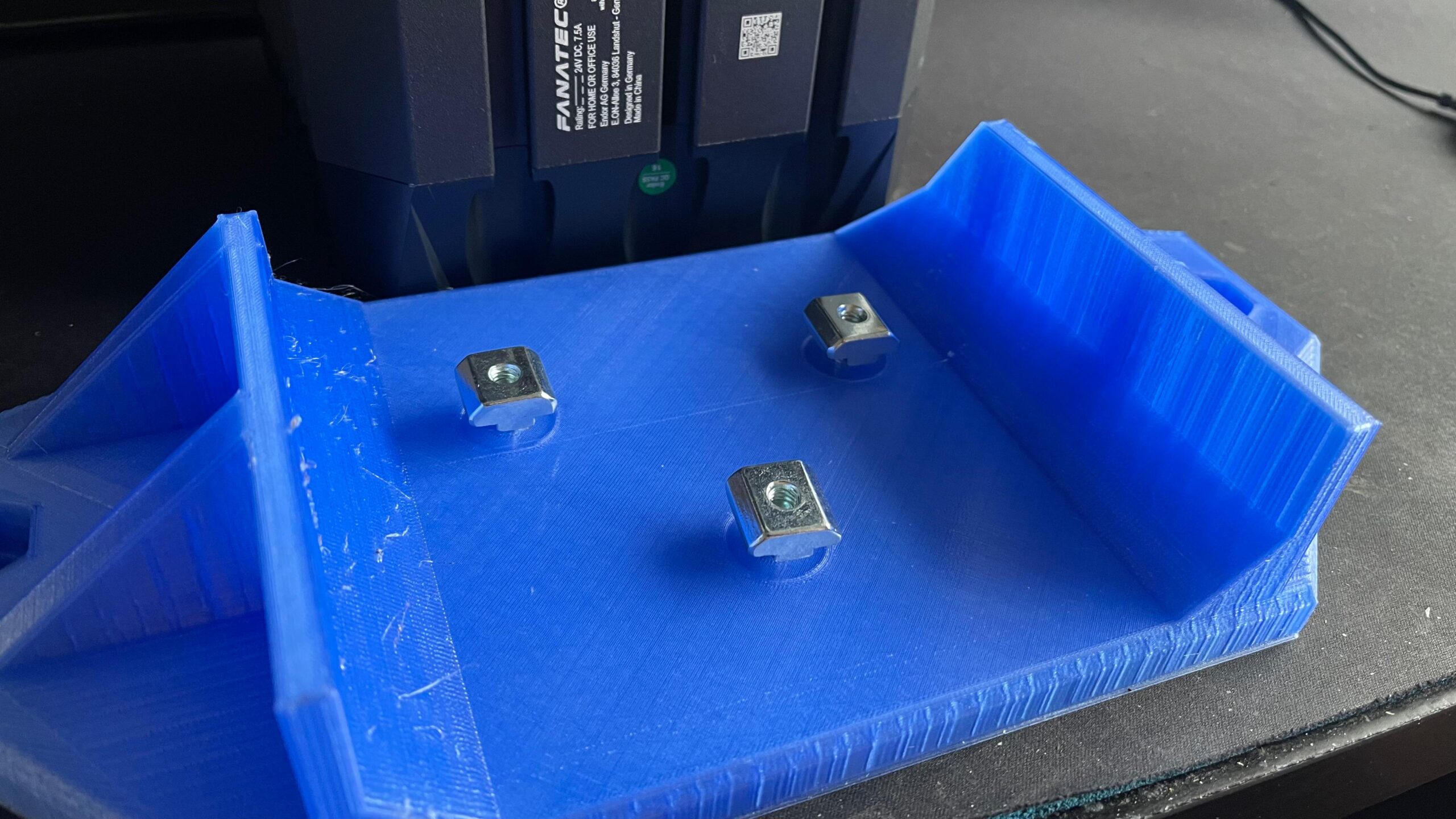

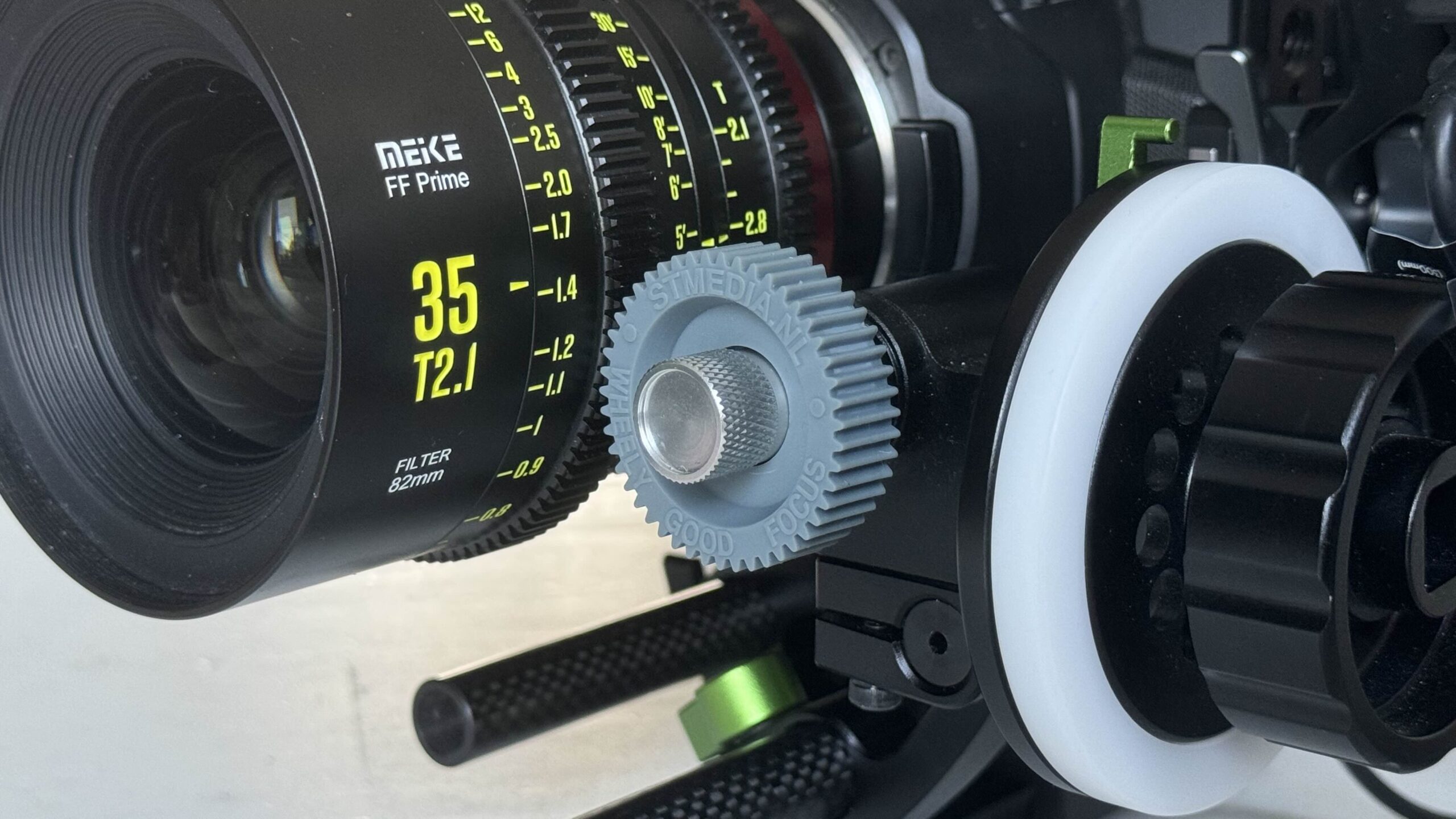

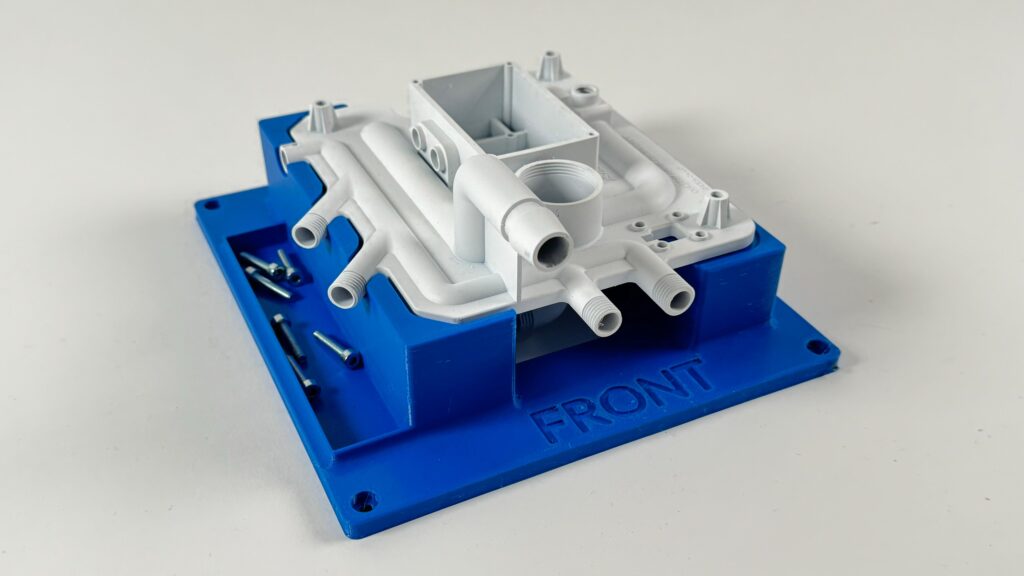

- Tool production: STMEDIA can help designing and producing custom tools, jigs and fixtures. This can be for video production. But also for different industries such as manufacturing.

- Prop production: Creating convincing props for video production can be a big challenge. STMEDIA can help with the design and production of high quality convincing props.

- Training for factories: STMEDIA can help manufacturers identify, design and print applications that speed up production, save money and make work safer and more enjoyable. We can support in the production, or training so you can start designing and printing yourself.