PRINTING ON-DEMAND ANYWHERE

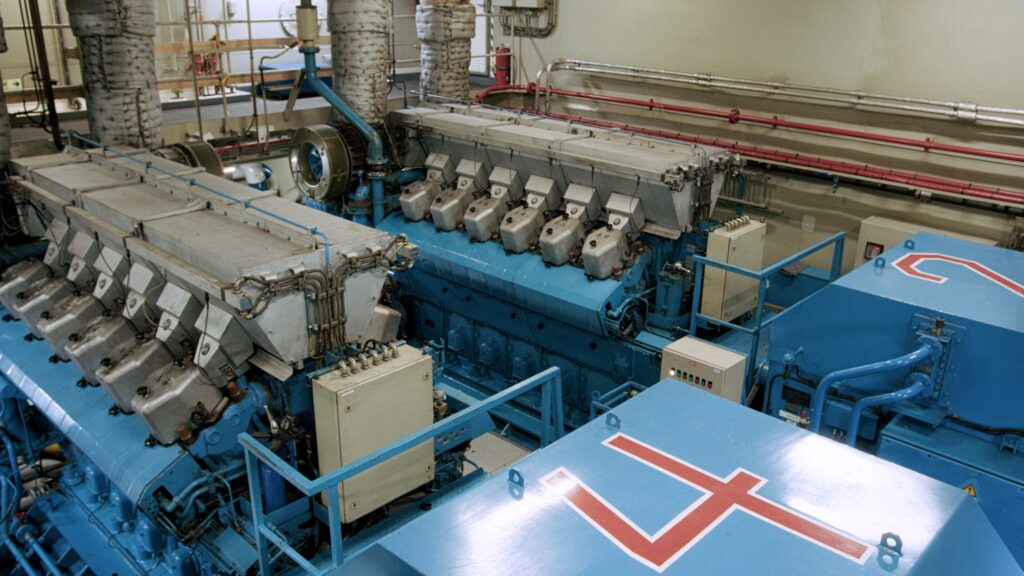

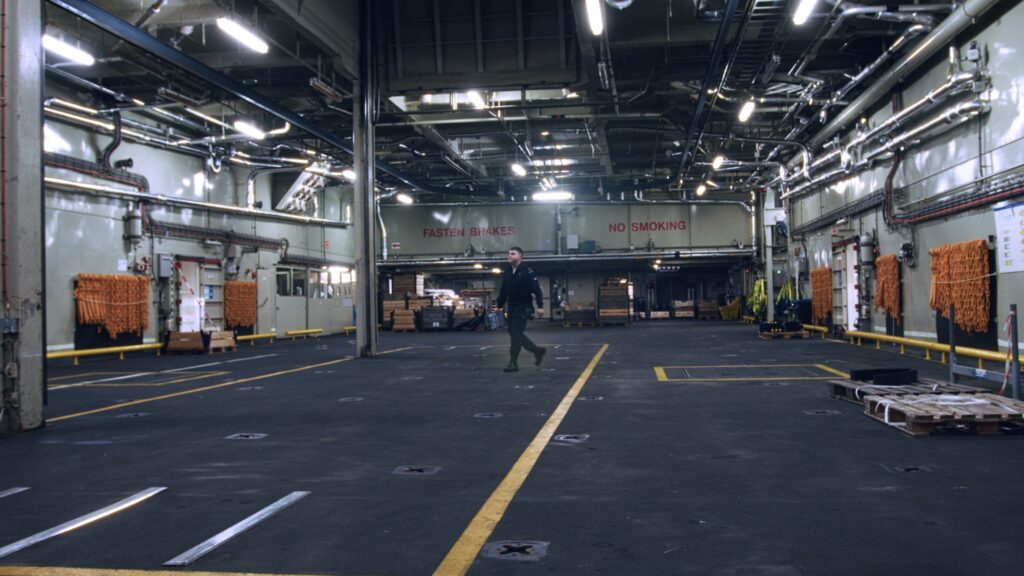

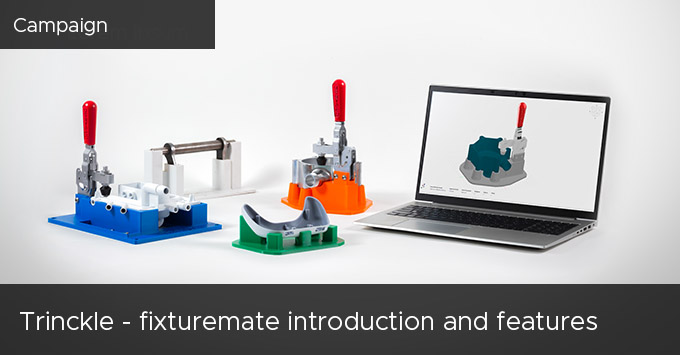

The Royal Netherlands Navy has adopted 3D printing as a solution to the challenge of maintaining a reliable supply of spare parts for their ships. By equipping each ship with UltiMaker 3D printers and a variety of materials, the Navy is able to produce spare parts on-demand and locally, reducing the need for long lead times and complex supply chains.

PRINTING WITH ADVANCED MATERIALS

The Royal Netherlands Navy is utilizing a range of materials in their 3D printing operations, including ABS, PETG, and composite carbon fiber. PETG is selected for its resistance to extreme temperature, wear, chemicals, and water and moisture absorption, making it ideal for maritime applications. The Navy’s use of composite carbon fiber allows for the production of lightweight yet strong parts, reducing the weight of the ships and improving their performance. By investing in these advanced materials, the Navy is ensuring that their 3D printed parts are durable and reliable, even in the harsh conditions of the open ocean.

The adoption of 3D printing is allowing the Navy to maintain operational readiness and efficiency, even in remote locations, and is a significant development that has the potential to revolutionize the way they maintain and operate their fleet.